SMT Contract Manufacturing Services

Specialized division offering complete prototyping and trial production for PCB and PCBA manufacturing

Electronic Contract Manufacturing Division

Established in 2017, the Electronic Contract Manufacturing Division of Wanxin Electric operates as an independent business unit specializing in full-process SMT contract manufacturing for PCB and PCBA production. Backed by the company’s strong industry expertise and technical capabilities, the division features a highly skilled engineering team and a dedicated component procurement department. It serves a diverse range of domestic and international clients in fields such as medical electronics, aerospace, robotics, power systems, telecommunications, industrial automation, and smart home technologies. The division delivers end-to-end manufacturing solutions, including PCB fabrication, BOM sourcing, SMT placement, PCBA assembly, prototyping, R&D sample production, small-batch trial runs, OEM/ODM services, DIP insertion, post-soldering, and comprehensive testing, programming, burn-in, and final assembly.

Three core advantages

Zero defects

From order to delivery, the pursuit of zero-defect delivery, only zero-defect delivery can make customers and their own interests.

Equitable services

Uniform processes for all clients, irrespective of order size or company scale.

Extended services

Provide engineering technology center, complete electronic laboratory for customers and themselves to jointly improve the level of research and development, common progress, service for the future.

Application scenarios

Medical Equipment

Purifies power, stabilizes voltage, and reduces losses. Provides zero-interruption protection against lightning and overload, with real-time power supply monitoring to ensure uninterrupted operation of life support systems and safe, accurate medical diagnostics.

Applicable scenarios: Operating room power systems, medical imaging centers, and ICU uninterruptible power distribution.

Automobile welding spots

Suppresses welding machine harmonics and voltage flicker within milliseconds. Intelligent capacitors dynamically compensate for reactive power, while protectors prevent overloads and lightning damage. Precision instruments monitor power quality to support the continuous, stable operation of welding robots.

Applicable scenarios: Body welding lines, battery tray robot welding stations, and suspension chain spot welding systems.

Strength Display

01

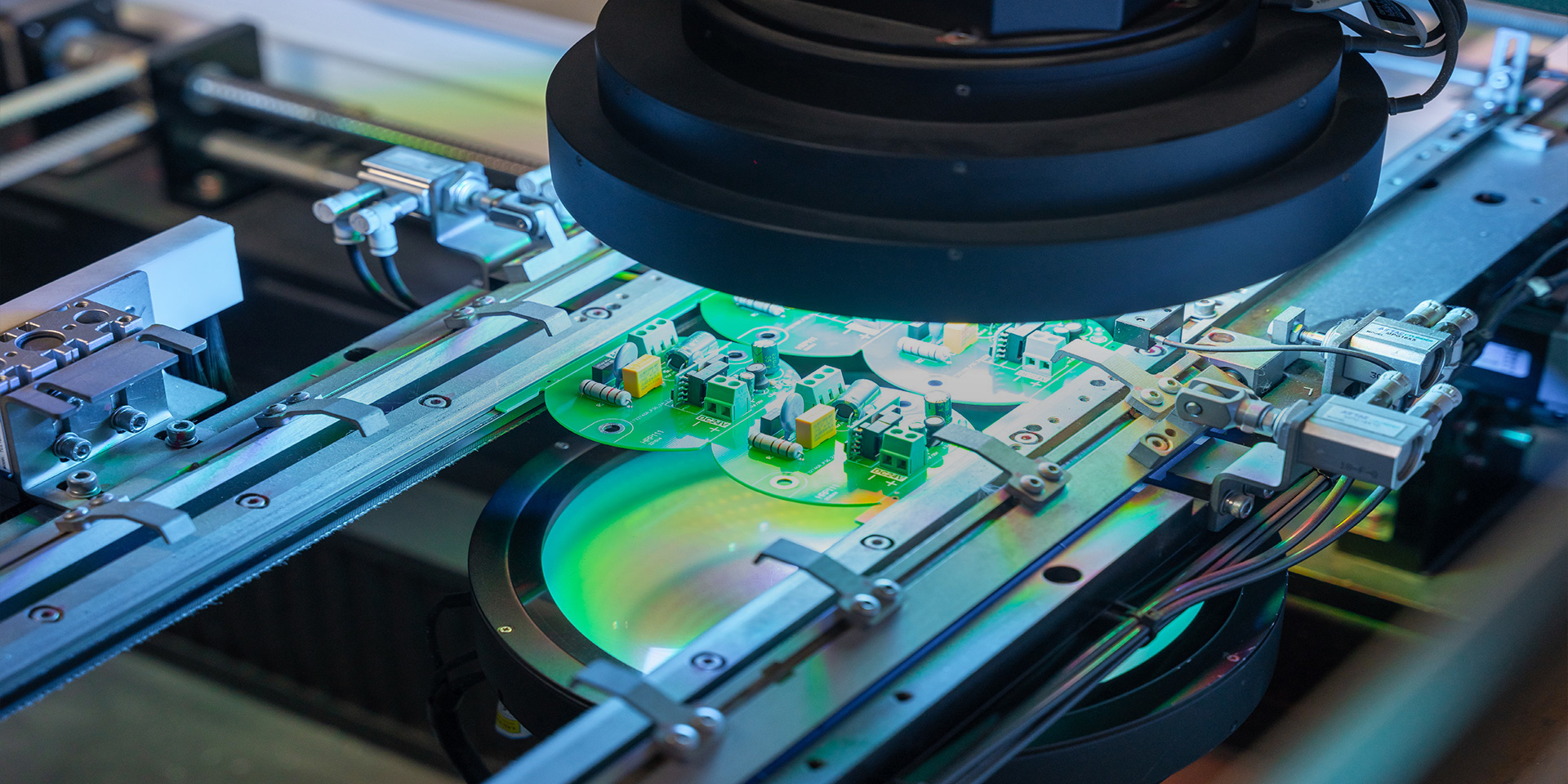

PCBA Processing

We operate eight high-speed SMT production lines equipped with Siemens systems, each capable of placing up to 140,000 components per hour (CPH).

02

Post-welding Processing

With two large wave welding lines, Panasonic automatic plug-in machine, 4 12 meters after the manual welding line, all skilled professional welding personnel.

03

Assembly Test

With 10 double speed chain assembly lines, a variety of standard / non-standard automatic calibration equipment, can also be customized development.

04

Research Center

With comprehensive test, electromagnetic compatibility test, environmental test overall realization equipment, with the provincial engineering research center qualification.

Overall Flow Control

With strong scientific research strength and perfect operation system, to provide you with high-quality products and excellent services

Receiving orders

01

Check

02

Warehousing

03

Engineering proofreading

04

Loading

05

Check of materials

06

Document verification

07

First material verification

08

Mass production

09

Process verification

10

Completion of work order

11

Packing and delivery

12

Customer acceptance

13